Benefits Of Volumetric Concrete

When ordering concrete, there are plenty of things that you need to consider, not least the type of concrete you actually need.

For the uninitiated, it can be confusing to work out what type of concrete works best for you; ready mix and volumetric concrete offer their own benefits and work better for different applications.

In this piece, we’re going to look at the benefits of volumetric concrete.

Advantages of Volumetric Concrete

One of the main benefits of volumetric concrete is that you’re guaranteed to have the right amount of concrete delivered to you. This means there’s no risk of over or under-ordering – the exact amount for the job at hand.

The various components of the concrete mix are stored and transported in separate compartments – this means that when the time comes to mix the concrete, it can be tailored and tweaked to your specifications. This is particularly helpful because it can take into account changing weather, which may alter the type of mix required.

Volumetric mixers can store up to double the amount of traditional drum mixers – 10m3, to be precise.

Volumetric vs. Drum (Barrel) Concrete

Wastage

Volumetric – There’s no wastage when it comes to volumetric concrete – as it is mixed on site, the correct amount can be mixed every time.

Drum – Concrete is mixed before being transported to the site – this means that anything that is not used goes to waste.

Truck Capacity

Volumetric trucks can store 10m3 of concrete within them – double the amount of concrete of their drum-based counterparts.

Flexibility

Volumetric – The fact it’s mixed on site means that it can be tailored as it goes: this means that should an unforeseen requirement arise, alterations can be made to the mix without halting or hindering the project.

Drum – Once the batch has been created and transported to the site, it cannot be changed. If a problem arises, the mix cannot be altered to cater for it, which means large amounts of concrete could be wasted.

How volumetric concrete mixers work

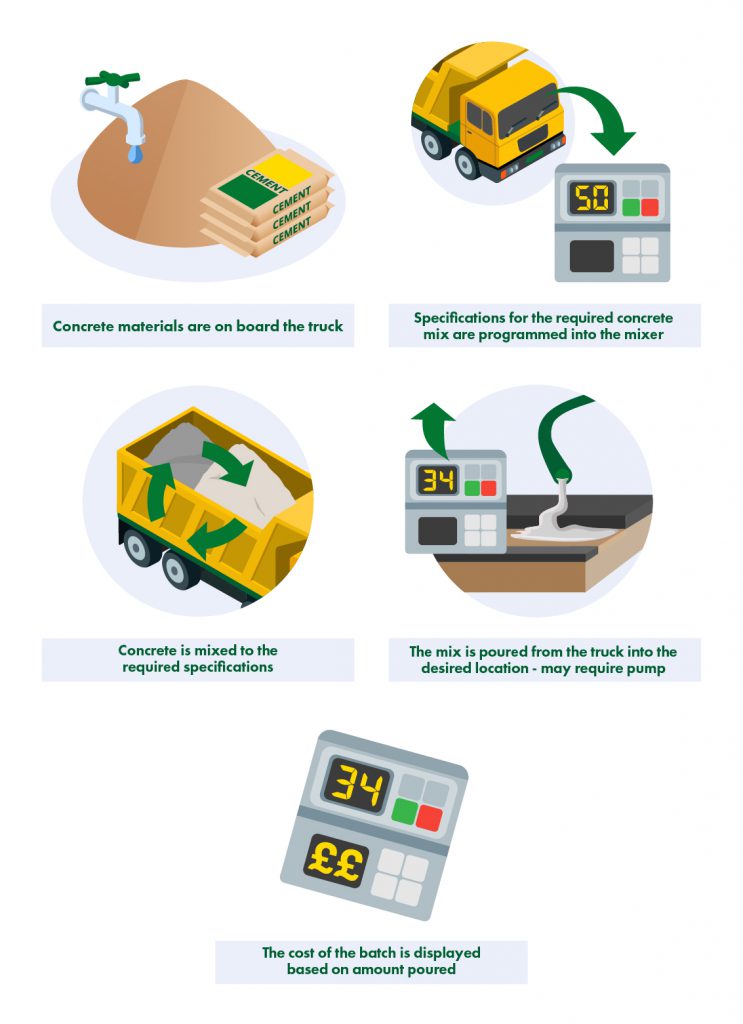

Volumetric concrete mixers are on board a truck that also carries the necessary raw materials for a concrete mix – aggregates, cement, water, fibres and any required additives. The specifications for the required concrete mix are programmed into the mixer – the specifications obviously vary depending on what the concrete is being used for (concrete footings, a driveway, or a patio, for example).

Once the mix has been created, it is poured from the truck into the desired location – this may require the use of a concrete pump – while this is going on, the exact volume of concrete poured is displayed, allowing the pour to stop when the necessary amount has been reached. Once finished, the amount displayed will determine how much the customer needs to pay for the batch.

Volumetric concrete is extremely popular for domestic, commercial and industrial applications of all types. With no wastage, exact ordering and no such thing as overpaying, it’s easy to see why it is so commonly used.

Neil Sullivan and Sons are leading providers of volumetric concrete for the domestic, commercial and industrial sectors. If you’d like to know more about our expert service, or to arrange the usage of our first class concrete, please contact us today.