How To Cure Concrete

Concrete is a strong, sturdy and reliable material, but in order for it to achieve said strength and reliability, the process of curing must be respected. For those undertaking their first concrete project, curing might be somewhat confusing, which is why the team at Neil Sullivan & Sons have created this guide.

What is concrete curing?

The curing of concrete is a process in where the rate of moisture loss from concrete is controlled and managed. Concrete curing often takes place after it has been poured into place, but it can happen during the manufacture of certain products in some circumstances.

Why does concrete need to be cured?

The primary reason for curing concrete is to increase the strength and durability of the material. As mentioned above, the rate of moisture loss is managed carefully during the curing process, and this is because the right amount of hydration needs to be maintained within the concrete to prevent problems such as shrinkage cracking and undue stress being placed on the material.

Freezing and thawing is also a threat to the structural integrity of concrete, and an adequate amount of hydration is required to minimise the risk of damage from this particular issue. If the rate of moisture loss is not managed, then the concrete will dry out and it won’t gain any more strength.

How do I cure concrete?

It may sound like a complex process, but curing concrete can be relatively simple in certain circumstances. If you have a small area of concrete, you can maintain the moisture levels by spraying the surface evenly and often – this is inadvisable for large surface areas, as you’ll end up wasting a lot of water.

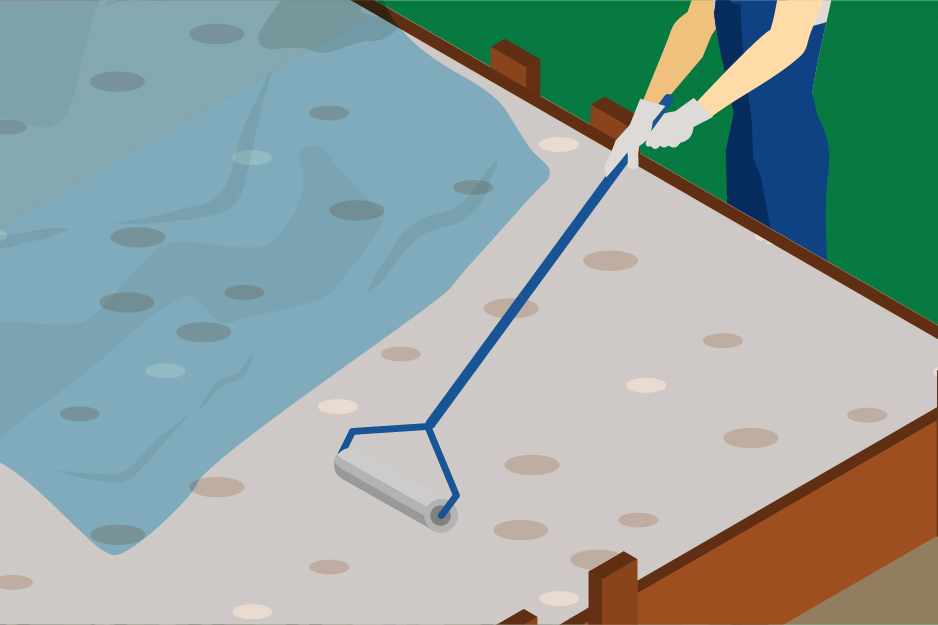

For the larger surfaces, there are two options: firstly, you can cover the surface in a plastic wrap to protect it, or use specialist oils and compounds that seal the surface and retain the moisture within it.

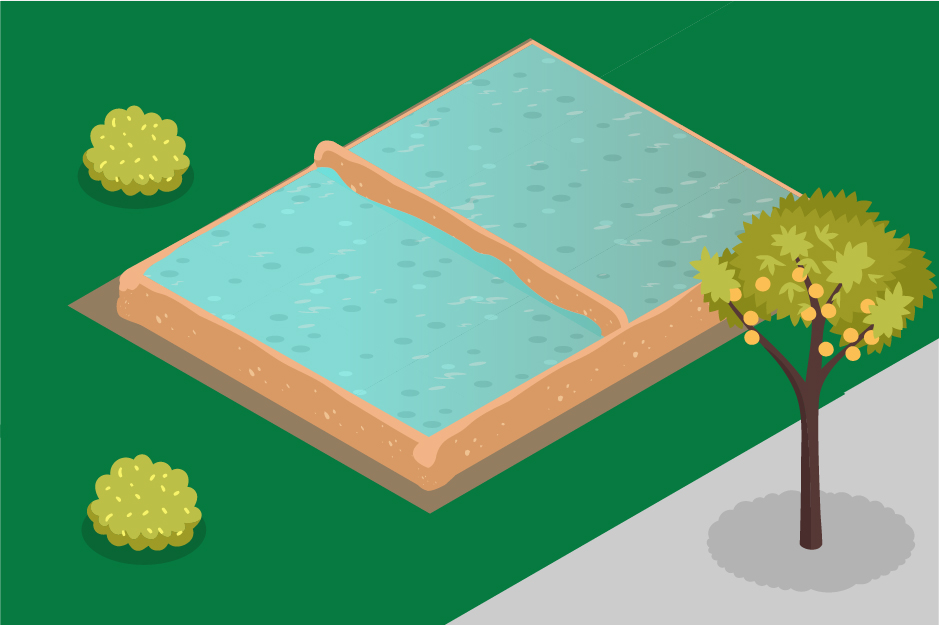

The last option is slightly more complex: build a ‘dam’ wall of sand around the surface area, and then flood inside the bordered area – this ensures constant watering.

When should I cure concrete?

Concrete will start to harden as soon as an aggregate is mixed with water. Once you’ve poured the concrete into place, you can immediately start with your curing process, whichever one you’ve opted for. It’s important that you’re ready to act, though, as you don’t want to waste time and allow the concrete to dry out.

How long does it take for concrete to cure?

Concrete curing takes a relatively long time. It will usually be hard enough to walk on after 24 hours, but the curing process is a gradual one. Concretes are designed with certain ‘strengths’ in mind – the maximum load bearing capability of the surface – and it usually takes around 28 days for the concrete to reach this designated strength.

Make sure to inform anyone who will be present during this time period of the curing process – use signage where possible to prevent people from walking on concrete before it’s cured.

Can I cure concrete in freezing temperatures?

Concrete curing is adversely affected by freezing temperatures. The hydration process is hindered and moisture loss is impeded by freezing temperatures, so if you are attempting to cure concrete at the height of winter, be sure to take advantage of some of the following protective measures:

- Windbreaks

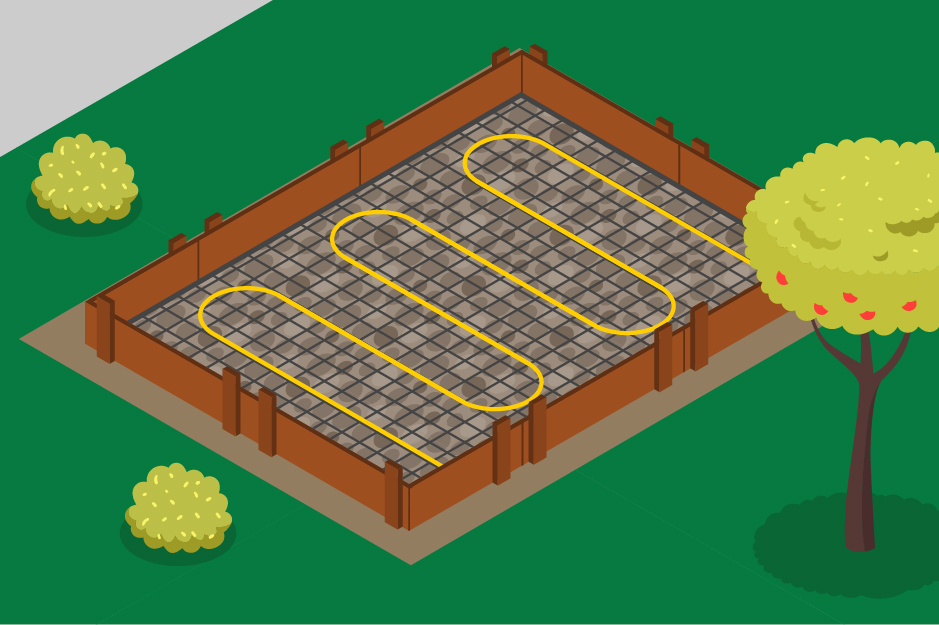

- Heating coils

- Insulating blankets

- Insulating sheets

- Straw-plastic

These materials will help retain heat in the concrete, which will aid the hydration process.

As you can see, curing concrete has a few caveats, but if you’re careful to avoid taking any risks, you’ll be able to enjoy a full-strength concrete surface in a matter of weeks.

Neil Sullivan & Sons are leading providers of concrete services for domestic and commercial customers throughout Essex. For more information about our work, please get in touch with us today.